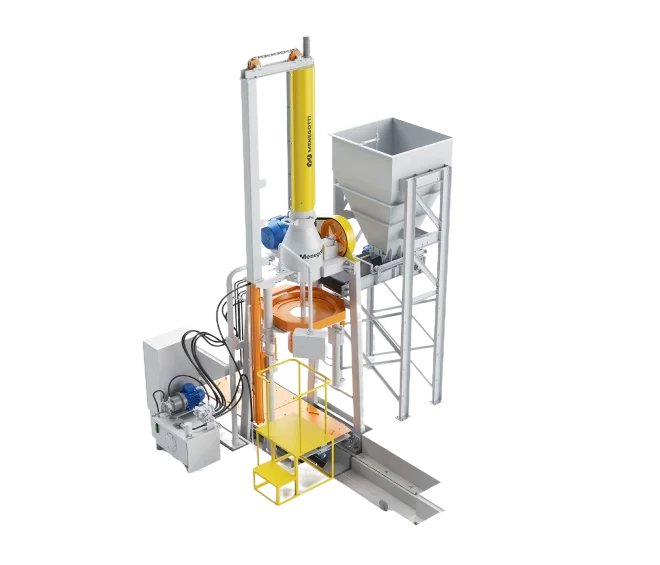

Semi-automatic machine designed to manufacture concrete pipes using the spin-compression process, both reinforced and non-reinforced, ranging from DN 300 to DN 600×1000/1500mm, with MF or PB finishes for stormwater drainage. This hydraulic press features easy operation and a robust structure, enabling large-scale pipe production.

Equipped with a special rotating device to ensure a superior pipe finish, it includes a head assembly made of highly durable materials resistant to axial compression forces and concrete abrasion. Recommended for industrial-scale production, it delivers high-quality output by utilizing radial compression and base vibration to enhance the compaction degree of the concrete.

Final products: concrete pipes (manholes), drains, and gutters.

| Description | Pieces per mold | Pieces per day | M² per day |

|---|---|---|---|

| Ø 300 | - | MF: 290 / PB: 240 | - |

| Ø 400 | - | MF: 330 / PB: 280 | - |

| Ø 500 | - | MF: 240 / PB: 200 | - |

| Ø 600 | - | MF: 280 / PB: 200 | - |

Note: The values in the table above may vary depending on the operating conditions of raw materials, workforce qualifications and training, mold changes, cleaning and maintenance periods of the equipment, and/or its unavailability, as well as unforeseen circumstances or force majeure.

| Internal diameter (mm) | Daily production (1000mm height) | Compact concrete volume per pipe (m³) | ||

|---|---|---|---|---|

| MF/TG/MH | PB/BS/PB | MF/TG/MH | PB/BS/PB | |

| 300 | 290 | 240 | 0,0343 | 0,0534 |

| 400 | 330 | 280 | 0,0595 | 0,0707 |

| 500 | 240 | 200 | 0,0916 | 0,1050 |

| 600 | 280 | 200 | 0,1239 | 0,1418 |

| Installed power (single carriage) | 40 HP |

| Installed power (double carriage) | 43 HP |

| Main motor power | 30 HP |

| Hydraulic unit motor power | 7.5 HP |

| Potência motor unidade hidráulica | 7,5 cv/hp |

| Hydraulic unit volume | 100 liters |

| Compressor head rotation speed: | 109 RPM |

| Working pressure | 70 Bar |