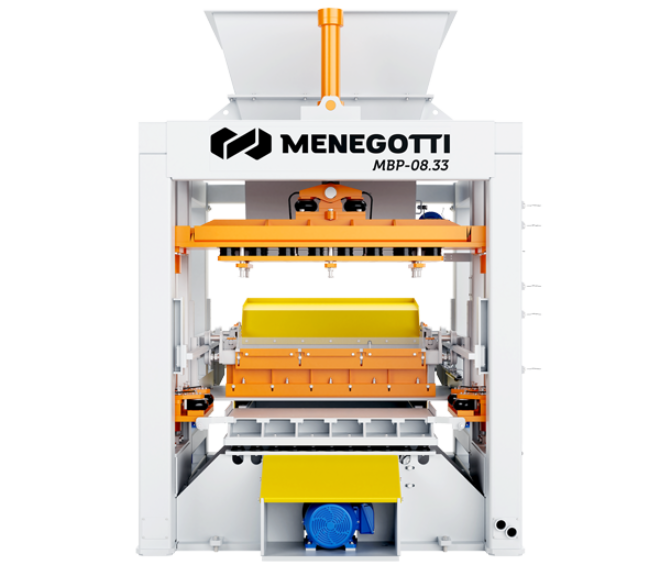

The MBP-08.33 is equipment designed for manufacturing concrete blocks and pavers using simultaneous vibration and compaction processes.

The equipment includes a hydraulic and electrical system that operates all mechanisms via a PLC (Programmable Logic Controller).

It features a quick mold and counter-mold change system, an intelligent high-efficiency pressing and vibration system, ensuring increased productivity and improved piece finishing. Additionally, it includes a dosing silo with a rotary feeding system, providing greater precision in material dosing.

Focusing on increased production, the MBP-08.33 is equipped with hydraulic drives and proportional valves on the drawer and feeder.

| Description | Pieces per mold | Pieces per day | Cycles/Min | M² per day |

|---|---|---|---|---|

| Paving: Pav “S” | 25 | 18.000 – 60.000 | 4,0 – 5,0 | 960 – 1200 |

| Paving: 200 x 100 x 80 mm | 33 | 63.360 – 79.200 | 4,0 – 5,0 | 1267 – 1584 |

| Hexagonal Tile 250 mm | 10 | 19.200 – 24.000 | 4,0 – 5,0 | 1067 – 1333 |

| Block 90 x 190 x 390 mm | 12 | 17.280 – 23.010 | 3,0 – 4,0 | – |

| Block 140 x 190 x 390 mm | 8 | 11.520 – 15.360 | 3,0 – 4,0 | – |

| Block 190 x 190 x 390 mm | 6 | 8.640 – 11.520 | 3,0 – 4,0 | – |

| Curbstone 120 – 150 x 300 x 1000 mm | 1 | 1.680 | 3,5 | – |

Note: The values listed in the table above may vary depending on the conditions of raw material operation, workforce qualification and training, mold setups, periods of cleaning and maintenance of equipment and/or its lack, unforeseen circumstances or force majeure.

| Machine Weight | 12 T |

| Voltage (Three-phase) | 220/380V |

| Total Installed Power | 85 CV |

| Silo Volume | 1,700 L |

| Pressing Force | 12.0 T |