It is a model that is well accepted in some regions of the country due to its appearance. As it is a single beam, it is easier to assemble. Its disadvantages are the use of a larger volume of concrete and the difficulty of transporting larger-span beams. It typically comes with the following accessories:

It is divided into Side Mold and Bed Mold. Accessories such as consoles for auxiliary beams and overhead cranes are used. The side mold is defined with one-meter side modules, allowing the positioning of the consoles to be adjusted according to the needs.

Simple Head Mold and Double Head Mold (Scissor Shed):

The pillar heads are the supports for the span beams and are fixed with tie rods that are anchored into the heads. The head mold is fixed at the end of the pillar mold so that the piece is cast in a single pour.

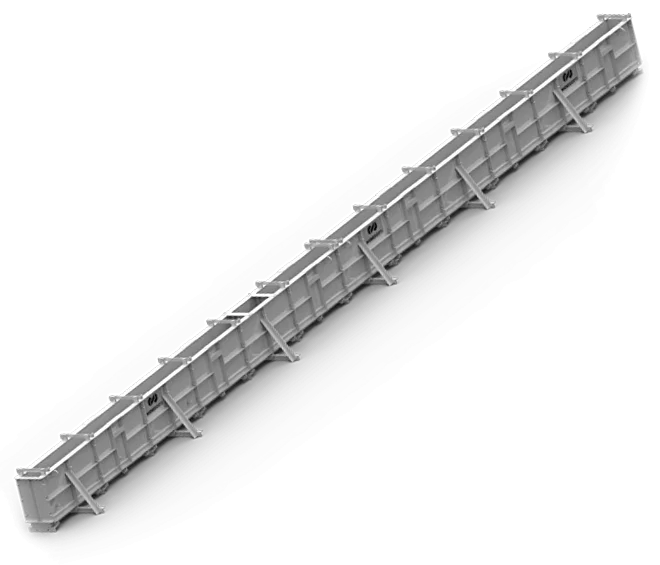

Scissor Beam Mold (Roof Beam):

This piece serves the purpose of forming the span of the shed and supporting the roof.

It is usually produced in a simple mold, as two pillars are needed for each scissor beam produced, since the scissor beam spans the entire width of the shed as a single piece.

|

SCISSOR BEAM |

||||

|---|---|---|---|---|

| SPAN (m) | DIMENSION “A” (mm) | DIMENSION “B” (mm) | DIMENSION “C” (mm) |

CONCRETE VOLUME (m³) |

| 22 | 24000 | 200 | 1474 | 2,022 |

| 21 | 23000 | 200 | 1424 | 1,931 |

| 20 | 22000 | 200 | 1374 | 1,842 |

| 19 | 21000 | 200 | 1324 | 1,754 |

| 18 | 20000 | 200 | 1274 | 1,667 |

| 17 | 19000 | 200 | 1224 | 1,582 |

| 16 | 18000 | 200 | 1174 | 1,498 |

| 15 | 17000 | 200 | 1124 | 1,416 |

| 14 | 16000 | 200 | 1124 | 1,335 |

| 13 | 15000 | 200 | 1074 | 1,306 |

| 12 | 14000 | 200 | 1024 | 1,178 |

| 11 | 13000 | 200 | 974 | 1,101 |

| 10 | 12000 | 200 | 974 | 1,026 |

| 9 | 11000 | 200 | 924 | 0,952 |