It is named as such because the end of the beam passes through the head of the column. This system is not commonly used today. It typically comes with the following accessories:

Poured Pillar Mold:

It is divided into Side Mold and Bed Mold. Accessories such as consoles for the auxiliary beam and overhead crane are used. The side mold is defined with one-meter side modules, allowing the positioning of the consoles to be adjusted according to the requirements.

Simple Head Mold and Double Head Mold (Pass-Through Shed):

The pillar heads are the supports for the span beams and are fixed by tie rods that are anchored into the heads. The Head Mold is attached to the end of the Pillar Mold so that the piece is cast in a single pour.

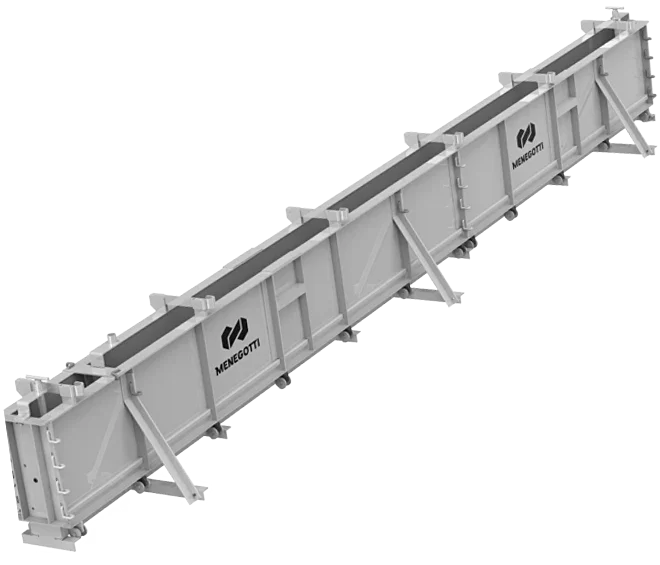

Pass-Through Beam Mold (Roof Beam):

This piece serves the function of forming the span of the shed and supporting the roof.

It is divided into Side Mold and Bed Mold.

Accessories for Sheds:

There are several common accessories for all types of sheds. Below are some models:

Lateral Console Mold, Internal Console Mold, and Chamfered Console Mold:

Auxiliary Beam / Baldrame Mold:

Baldrame beams serve to tie the pillars and foundation together, as well as provide support for the walls.

This mold consists of a Side Mold, Metal Mold, and Small Separator to form the fitting (housing for the console).

| Auxiliary Beam Mold and Baldrame Beam Mold | ||||||

|---|---|---|---|---|---|---|

| DIMENSION “A” (mm) | DIMENSION “B” (mm) | DIMENSION “C” (mm) | DIMENSION “D” (mm) | DIMENSION “E” (mm) | CONCRETE VOLUME (m³) | |

| 6000 | 300 | 120 | 150 | 150 | 0,209 | |

| 6000 | 300 | 150 | 150 | 150 | 0,262 | |

| 6000 | 300 | 200 | 150 | 150 | 0,350 | |

| 6000 | 400 | 150 | 200 | 200 | 0,347 | |

| 6000 | 400 | 200 | 200 | 200 | 0,463 | |

| 6000 | 500 | 150 | 250 | 200 | 0,434 | |

| 6000 | 500 | 200 | 250 | 200 | 0,579 | |

| 6000 | 600 | 200 | 250 | 200 | 0,698 | |

Truss Mold:

The truss mold is used for supporting and fixing roofing materials (such as fiber cement, aluzinc, galvanized sheet, etc.). There are two types of molds for reinforced concrete trusses:

Dimensional Table for “L” Type Truss Mold:

| “L” TYPE TRUSS MOLD | ||||

|---|---|---|---|---|

| SPAN (m) | DIMENSION “A” (mm) | DIMENSION “B” (mm) | CONCRETE VOLUME (m³) | |

| 04 | 5600 | 180 | 0,043 | |

| 05 | 6600 | 180 | 0,050 | |

| 06 | 7600 | 180 | 0,061 | |

| 07 | 8600 | 200 | 0,078 | |

Dimensional Table for “T” Type Truss Mold:

|

“T” TYPE TRUSS MOLD

|

||||

|---|---|---|---|---|

| SPAN (m) | DIMENSION “A” (mm) | DIMENSION “B” (mm) | DIMENSION “C” (mm) | CONCRETE VOLUME (m³) |

| 04 | 5600 | 110 | 150 | 0,057 |

| 05 | 6600 | 110 | 150 | 0,067 |

| 06 | 7600 | 110 | 150/180 | 0,076/0,093 |

| 07 | 8600 | 110 | 150/180 | 0,086/0,105 |

Closure Slab Mold:

Closure slabs are precast slabs used as walls for sheds. Their main advantage is the reduced assembly time compared to brick.

This mold is double adjustable (two pieces per pour), usually for wall thicknesses of 60/80/100/120/150mm with a height of 1250mm and a length of 6000mm, but it can also be produced with special measurements (provided by the customer). Another form system used for producing these slabs is the tilting system, consisting of a movable tray capable of producing one piece per day.

Dimensional Table for Closure Slab:

| CLOSURE SLAB | ||||

|---|---|---|---|---|

| DIMENSION “A” (mm) | DIMENSION “B” (mm) | DIMENSION “C” (mm) | CONCRETE VOLUME (m³) | |

| 6000 | 1250 | 60 | 0,447 | |

| 6000 | 1250 | 80 | 0,597 | |

| 6000 | 1250 | 100 | 0,747 | |

| 6000 | 1250 | 120 | 0,897 | |

| 6000 | 1250 | 150 | 1,1223 | |

Adjustable Pillar / Beam Mold:

The Adjustable Pillar / Beam Molds are designed to allow the production of various sizes of Pillars or Auxiliary Beams using the same mold. They offer adjustments in increments of 50mm for both width and height. The maximum and minimum dimensions must be provided by the customer. The width adjustment is made by changing the position of the hinge on the base of the mold, which has several pre-determined holes for the desired adjustment. The height adjustment is done using a telescopic regulator, also with several possible positions. These molds can be produced in Double Mold or Single Mold:

Adjustable Pillar Mold Dimensional Table

|

ADJUSTABLE PILLAR FOR SHED |

|||

|---|---|---|---|

| DIMENSION “A” (mm) | DIMENSION “B” (mm) | DIMENSION “C” (mm) | CONCRETE VOLUME (m³) |

| 6000 A 20000 | 200 A 800 | 150 A 600 | ——— |

Pi Slab Mold:

These molds are used to create mezzanines in sheds. Their dimensions depend on the span to be covered and the load that will be applied. The mold comes with a length limiter and small separators to form the fitting for support on the auxiliary beam. By adding height adjusters, the customer can produce pieces with smaller heights according to the project’s needs. The most common dimensions are 200/300/400/500mm in height, 1250mm in width, and 6000mm in length.

| PI SLAB | ||||

|---|---|---|---|---|

| DIMENSION “A” (mm) | DIMENSION “B” (mm) | DIMENSION “C” (mm) | CONCRETE VOLUME (m³) | |

| 6000 | 1500 | 500 | 0,894 | |

| 6000 | 1500 | 300 | 0,676 | |

| 6000 | 1500 | 200 | 0,567 | |

| 6000 | 1250 | 300 | 0,609 | |

| 6000 | 1250 | 200 | 0,500 | |

Stair Mold:

They are used for access to the second floor of sheds or for use in buildings. Their dimensions depend on the client’s project. The mold is usually cast at a 90° angle to its position of use and is made with fixed hinges where the side with the steps is fixed, and the smooth side (the underside of the stair considering the position of use) is movable. The mold can be single or double and can be made for a specific stair model or an adjustable mold can also be made, capable of accommodating various models.

Dimensional Table for Stairs:

| PRECAST STAIR | |||||

|---|---|---|---|---|---|

| DIMENSION “A” (mm) | DIMENSION “B” (mm) | DIMENSION “C” (mm) | DIMENSION “D” (mm) | ANGLE ADJUSTMENT |

CONCRETE VOLUME (m³) |

| 200 à 2000 | 150 | 1750 | 730 | 4 à 17 | —– |

| 200 à 2000 | 150 | 1500 | 730 | 4 à 17 | —– |

| 200 à 2000 | 150 | 1250 | 730 | 4 à 17 | —– |