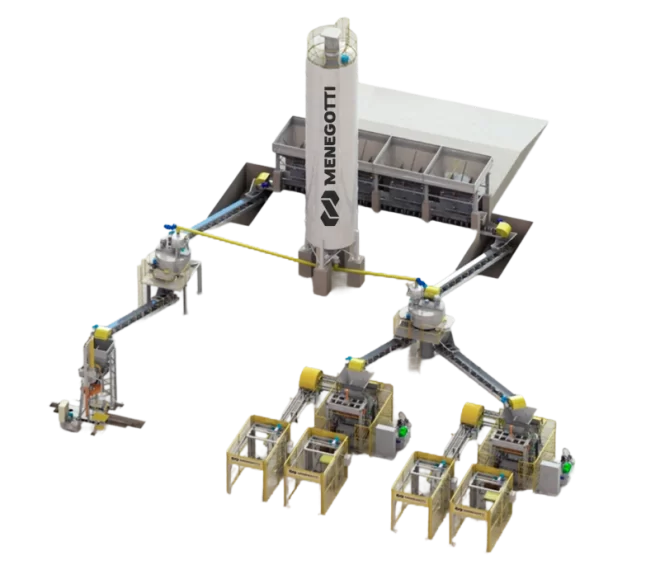

It is a customized system designed to arrange all the aggregates and cement in a planetary mixer, responsible for the homogeneous mixing of the components and feeding the equipment. It is typically composed of aggregate silos, weighing conveyor, weighing system, conveyor belt, cement silo (or sack-breaker silo), cement scale, cement weighing system, screw conveyor, planetary mixer, and its platform. The system includes an Automation unit responsible for the automatic control of all functions of the plant. Its electrical, hydraulic, and pneumatic peripherals are from well-known suppliers in the market, with a broad network of national and international distribution.

Aggregate Silo

Storage unit for solid aggregates

Aggregate Weighing System

System 1 – Conventional Weighing

Weighing conveyor system composed of:

System 2 – Individual Weighing

Composed of 0.7 m³ silos (one for each aggregate bin), each with four “z” load cells, with a capacity of 500 kg each (individual weighing system).

Conveyor Belt

Belt for transferring raw materials and concrete within the dosing and feeding system.

Cement Silo

Capacity for 50, 70, or 75 m³ (70, 98, and 105 tons, respectively) density = 1,400 kg/m³.

Sack-Breaker Cement Silo

A more economical system recommended for small installations (or where bulk cement is unavailable). In this system, the sack is manually opened by the operator.

Belt for transporting aggregates in the weighing system, with reversible operation capability.

Cement Scale

Screw Conveyor

Cement conveyor type auger. Designed to transfer cement from the silo to the mixer scale.

Automation – Central Electrical Panel

Composed of an electrical panel housing all the electrical components (circuit breakers, thermal relays, and contactors for motor protection). Equipped with a PLC that controls the entire plant operation, aggregate and cement weighing, water dosing, and equipment operation, as well as storing production data such as batch recipes. The panel also includes interfaces for PLC actuators, water dosing, cement, and aggregate weighing cells.

Water Dosing System

System for automatically dosing water for mixing and concrete production, equipped with:

Additive Dosing System

System for automatically dosing additives for mixing and concrete production, equipped with:

Planetary Mixer

Equipment for concrete production, designed with a planetary system for more homogeneous mixing. It features a paddle system that rotates around a central axis and a paddle system that scrapes the concrete from the mixer walls. The mixer is lined with interchangeable carbon steel plates on the sides and bottom, and its paddles are made of white cast iron.

Optional Features

| Motor Power | MP-7.5: 10 hp / MP-20: 20 hp / MP-50: 50 hp / MP-60: 60 hp |

| Maximum Concrete Volume per Cycle | MP-7.5: 0.175 m³ or 400 kg / MP-20: 0.45 m³ or 1,000 kg / MP-50: 0.75 m³ or 1,800 kg / MP-60: 1 m³ or 2,400 kg |