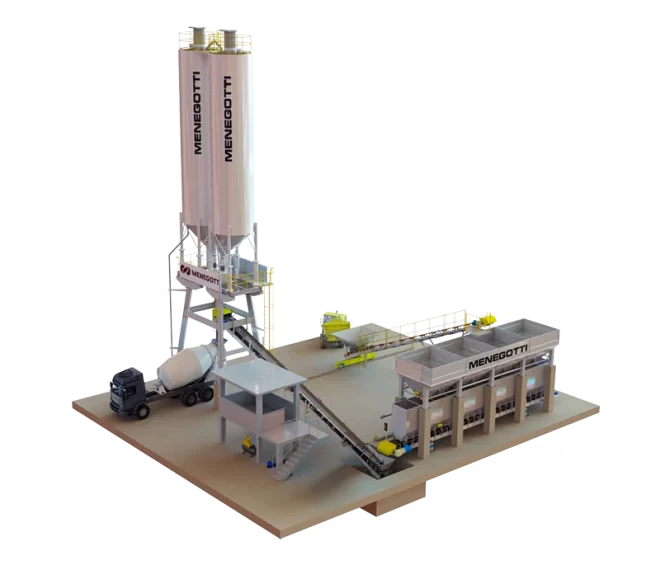

A customized structure designed to load all aggregates and cement into a mixing system, typically a concrete mixer truck. It generally consists of aggregate bins, extractor conveyor belt, aggregate weighing system, cement silo, cement silo platform, and cement scale. The system includes an electrical and pneumatic panel. Its electrical, hydraulic, and pneumatic peripherals come from well-established suppliers with extensive national and international distribution networks.

TOW-GO

Designed for dosing cement and aggregates to supply concrete mixer trucks, the Menegotti TOW-GO concrete plant features a double aggregate weighing silo with a 14 m³ capacity per bin, a conveyor belt for truck loading, a cement scale with a capacity of 14 tons, two cement silos with a 70 m³ capacity each, and an electrical panel. This setup can also include a volumetric dosing system or a weighing system.

The plant’s operation can be manual or semi-automatic. In the semi-automatic system, dosing is controlled via a human-machine interface, enhancing productivity and concrete quality.

The standout feature of the Menegotti TOW-GO concrete plant is its speed in truck loading. Thanks to its dual independent weighing silos, one bin can be refilled by a front loader while the other supplies the truck.

| Installed Power | 24 kW |

| Cement Weighing Capacity | 4 tons |

| Aggregate Weighing Volume Capacity | 14 m³ |