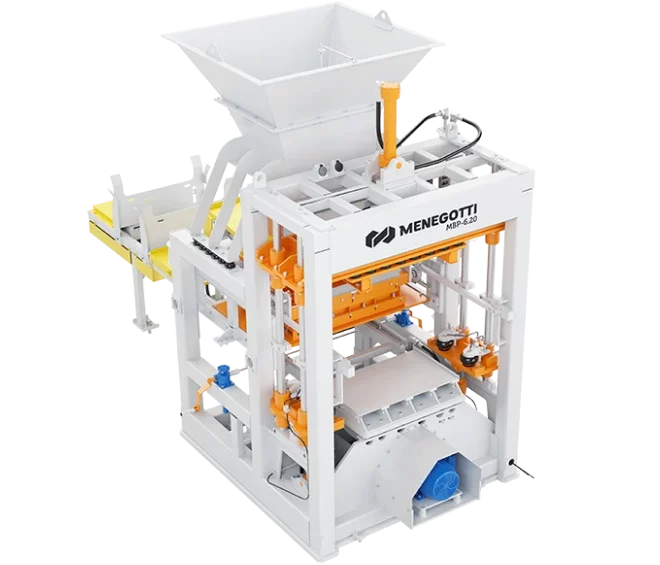

The MBP-6.20 automatic machine for manufacturing concrete blocks and pavers features simultaneous vibration and compression processes, operated via PLC, hydraulic, and electrical systems.

It is equipped with a quick mold change system, ensuring greater agility in machine setup. Its intelligent pressing/vibration system enables productivity increases based on Industry 4.0 concepts, with all high-energy-efficiency electrical drives.

| Description | Pieces per mold | Pieces per day | M² per day |

|---|---|---|---|

| Paving: Pavi “S” | 16 | 23,040 - 30,720 | 461 - 614 |

| Paving: 200 X 100 X 80 mm | 20 | 28,800 - 38,400 | 576 - 768 |

| Hexagonal Tile 250 mm | 6 | 8,640 - 11,520 | 480 - 640 |

| Block 90 x 190 x 390 mm | 9 | 10,800 - 12,960 | - |

| Block 140 x 190 x 390 mm | 6 | 7,200 - 8,640 | - |

| Block 190 x 190 x 390 mm | 4 | 4,800 - 5,760 | - |

| Curbstone 120 x 140 x 350 x 650 mm | 1 | 1,440 - 1,920 | - |

Note: The values in the table above may vary depending on the operating conditions of raw materials, workforce qualifications and training, mold changes, cleaning and maintenance periods of the equipment, and/or its unavailability, as well as unforeseen circumstances or force majeure.

| Machine Weight | 8 T |

| Voltage (Three-phase) | 220 / 380 V |

| Total Installed Power | 57 cv |

| Silo Volume | 1000 liters |