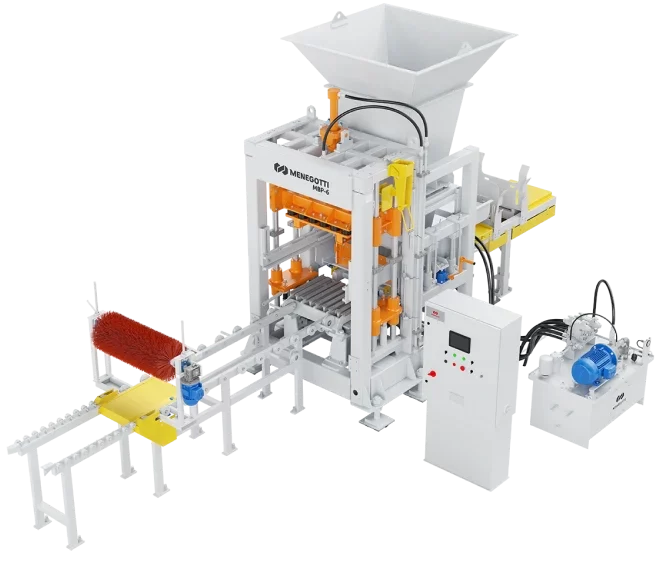

The MBP-6 HSC is equipment designed for manufacturing concrete pavers and blocks, utilizing simultaneous vibration and compression processes. It includes a hydraulic and electrical set, responsible for operating all mechanisms via a PLC (Programmable Logic Controller), eliminating the need for manual operation.

This vibropress is ideal for large-scale production of partition and structural blocks as well as high-strength pavements due to its efficient and modern vibration and compression processes.

Produces items such as: partition blocks, structural blocks, half-blocks, channels, half-channels, slabs, hexagonal tiles, cobblestones (Dutch), Pav “S” (unistein type) pavers, and curbstones.

It can be adapted to the MSAP-4/6 Pallet Manipulator System for further production line automation or the Transpalete Manual Clamp.

| Description | Pieces per mold | Pieces per day | M² per day |

|---|---|---|---|

| Paving: Pavi “S” | 10 | 16,800 - 19,200 | 336 - 384 |

| Paving: 200 X 100 X 80 mm | 12 | 20,160 - 23,040 | 403 - 461 |

| Hexagonal Tile 250 mm | 4 | 5,040 - 5,760 | 280 - 320 |

| Block 90 x 190 x 390 mm | 6 | 7,200 - 8,640 | - |

| Block 140 x 190 x 390 mm | 4 | 4,800 - 5,760 | - |

| Block 190 x 190 x 390 mm | 3 | 3,600 - 4,320 | - |

| Curbstone 120 x 140 x 350 x 650 mm | 1 | 1.440 | - |

Note: The values in the table above may vary depending on the operating conditions of raw materials, workforce qualifications and training, mold changes, cleaning and maintenance periods of the equipment, and/or its unavailability, as well as unforeseen circumstances or force majeure.

| Machine Weight | 5.5 T |

| Voltage (Three-phase) | 220 / 380 V |

| Total Installed Power | 50 hp |

| Silo Volume | 1000 liters |